|

|

Build Your Online Product Catalogs?

| Product Name: |

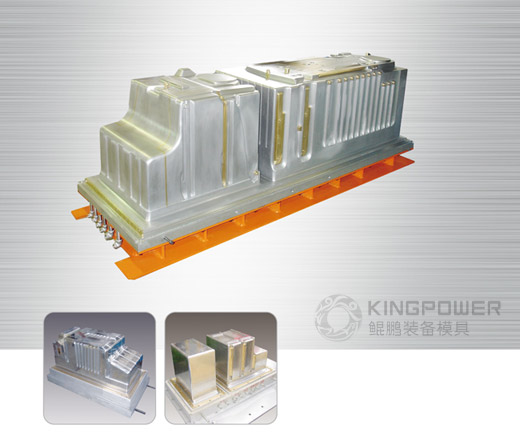

Vacuum Forming (thermoforming) Male Mould for Refrigerator Cabin

|

| Supply Ability: |

|

| Related proudcts |

vacuum forming, thermoforming, |

| Specifications |

Male Mould |

| Price Term: |

FOB/CIF |

| Port of loading: |

any port in China |

| Minimum Order |

1 set |

| Unit Price: |

|

|

The working procedures of male mould forming are as following: Soften up the plate through heating, then stretch the plate through bubbling, and that will be a sealed cavity, vacuumize it and make it subpressure, then the plate will adsorb on the surface of the mould, cooling it, then the product formed.

The mould consists of mould core, base, sealing plate, core-pulling mechanism, heating system, top and bottom reduction frames, etc.

This mould is made from ZL401 and C5(Europe), so it is highly glabrous, no air hole, no loose and other defects. The core-pulling mechanism use the accuracy straight guide and straight bear guidance, core-pulling module use copper with high thermal conductivity, the pneumatic parts use high quality type and other import components, such as SMC, FESTO, etc.

|

| Company: |

Anhui KingPower Equipment and Mould Manufacture Co., Ltd

|

| Contact: |

Ms. Ma Tiffany |

| Address: |

No.459 North Rd, Chengdong Industrial Zone |

| Postcode: |

239064 |

| Tel: |

86 550 3161356 |

| Fax: |

86 550 3162222 |

| E-mail: |

|

|

|

|